History of Rengo

The Story of Rengo

1920-The Foundation of Business Is Established

| 1920 | Rengo Shiki K.K. was established. The head office was located in Tokyo with plants situated in Tokyo, Kawasaki, Nagoya and Osaka. |

| 1923 | Rengo acquired the Osaka-based Nippon Seishi and renames it the Chifune Plant. The Tokyo Plant burnt down due to the Great Kanto Earthquake. |

| 1936 | An integrated plant (Yodogawa Plant) having all processes required to produce paperboard and corrugated boxes—the largest of its kind in the Orient—was completed in Osaka. |

| 1945 | Six plants in Japan are destroyed by fire during the war while all overseas assets are requisitioned. |

-

Recognizing that Inoue was working hard, Tokyo Electric President Yoshio Shinjo suggested to him, "Why don't you make Sanseisha a stock company? If you do so, we will provide our share of support." Based on this recommendation, it was decided that Sanseisha and two of its subsidiaries, as well as Eiritsusha and Azuma Shiki Seisakusho, both of which worked with Sanseisha to deliver corrugated board for electric bulbs would merge to form Rengo Shiki K.K. A general meeting for founding the new company took place on Sunday, May 2, 1920. On the same day, Japan's first May Day rally was held at Ueno Park in Tokyo. It was a period when various industries were proliferating and the number of plant workers was increasing rapidly. The new company was capitalized at ¥2 million with its head office located in Taihei-cho, Honjo-ku, Tokyo. Mr. Shinjo was appointed president, and Inoue became the head managing director who was responsible for daily operations. The company had 126 employees.

It was with the progress of industrialization in Japan that Inoue's corrugated packaging business can be said to have got under way. In 1923, three years after the establishment of the new company, Rengo Shiki absorbed Nippon Seishi, a paperboard manufacturer based in Osaka, and built manufacturing processes for corrugated board and boxes at the site of the manufacturer. This became Japan's first integrated plant to produce from paperboard to corrugated boxes. Since the acquisition required large amounts of funds, many objected to the plan in the company and interventions were made from outside, but Inoue overcame these objections and interventions and managed to realize the merger, indicating his firm determination for business expansion to both people inside and outside of the company.

One month after the merger, the Great Kanto Earthquake occurred. The head office and plant in Tokyo were destroyed and damage totaled ¥300,000. The integrated manufacturing plant in Osaka made up for the decline in performance, however. Later, Inoue expressed his thoughts, saying, "Without the merger, our company would not exist today." After the earthquake, he immediately rebuilt the Tokyo plant, and in 1926, he relocated the head office to Osaka and became president, a post that had been vacant for five years since President Shinjo had passed away.

At the end of the Taisho period (1912–26), Rengo Shiki promoted corrugated boxes under the name "packing cases." Soon the products came to be known as the "Mazda lamp box" in eastern Japan and as the "Fukusuke tabi (Japanese socks) box" in western Japan, and they steadily gained popularity, exemplified by the fact that it was reported in the financial column of a newspaper that paper boxes were stronger than wooden ones. Larval silkworm raising boxes (Photo 4), an application of corrugated board, were found by silk-raising farmers to be useful and became a hit product. In the early Showa period (1926-1989), in an effort to meet new demand, Rengo Shiki developed packaging for exported canned foods, china and porcelain (Photo 5), beer and other products (Photo 6), as well as for frozen salmon (Photo 7). Corrugated boxes were recognized as indispensable materials for packaging, transportation and storage.

-

Photo 4: A larval silkworm raising box and a box for transporting silkworm eggs

Photo 4: A larval silkworm raising box and a box for transporting silkworm eggs -

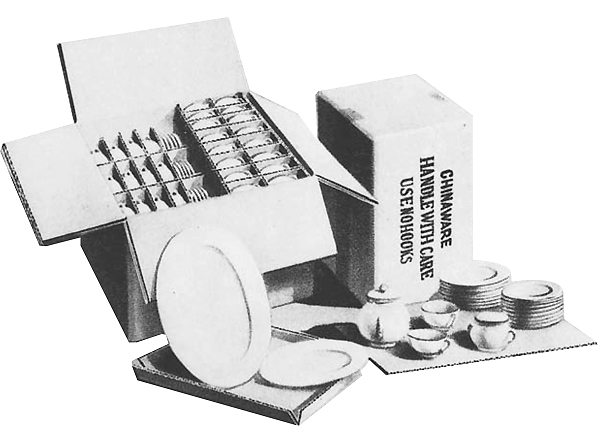

Photo 5: "Packed china and porcelain for export, which conform to the U.S. general transportation regulations"

Photo 5: "Packed china and porcelain for export, which conform to the U.S. general transportation regulations" -

Photo 6: A box for bottled beer for export

Photo 6: A box for bottled beer for export -

Photo 7: A box for frozen salmon

Photo 7: A box for frozen salmon

-

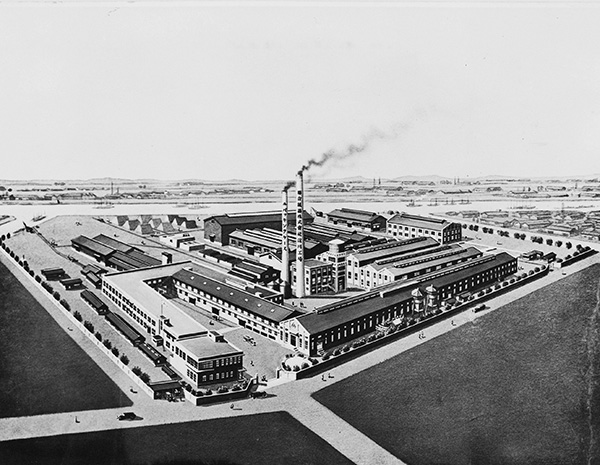

Photo 8: View of the Yodogawa Plant

Photo 8: View of the Yodogawa Plant

In order to meet strong demand, Rengo Shiki planned to build a large integrated plant and completed the Yodogawa Plant in Obiraki, Fukushima-ku, Osaka-shi after seven year's construction, beginning in 1930 (Photo 8). The entire new plant consisted of leading-edge equipment, including a power generation system, two paper machines, a machine for manufacturing corrugated boxes and other equipment. The paper machines were designed by Rengo Shiki's engineers, and the modern floor plan for the corrugated board plant was laid by the company's personnel on their own. Visitors from Europe and North America even marveled at the plant, saying, "I didn't realize that such an advanced plant existed in an Oriental country like Japan!"

In 1936, Tokyo Electric, the largest customer, informed Rengo Shiki that it would carry out a plan for manufacturing corrugated board and corrugated boxes in-house. After long consideration, Inoue solved the problem by forming a capital tie-up with Tokyo Electric and taking over a folding carton plant in Kawaguchi-shi, Saitama Prefecture and a paper mill in Katsushika, Tokyo.

At about this time, Rengo Shiki built plants in Kingjo, Korea and Taipei, Taiwan and then in Mukden (Fengtian), Manchuria and in the Chinese cities of Tianjin and Shanghai, but it was soon forced into production for meeting military demand as Japan entered the Pacific War and built up its war structure. In 1945, seven plants in Japan burnt down due to air raids by U.S. bombers while all of the assets the company had in Korea, Taiwan and China were requisitioned.

-