Relationship with SDGs

Rengo contributes toward achieving the SDGs in all processes, from raw material procurement to sorting,

collection, and recycling. Here, we introduce how we work on environmental and social issues.

ManufactureUndertaking recycling initiatives

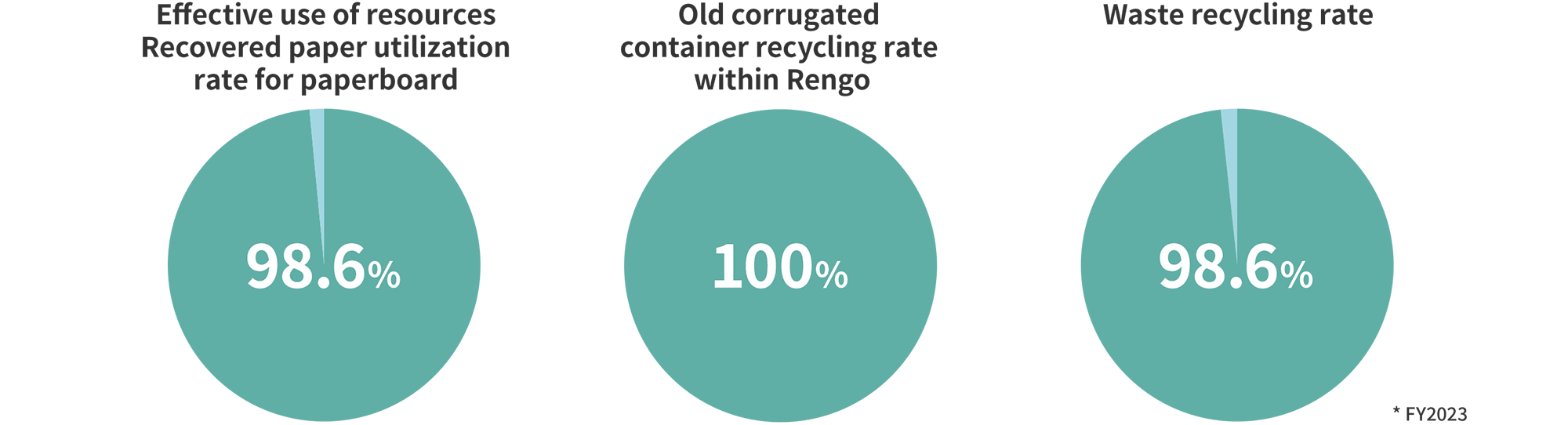

Rengo carefully uses limited resources and strives to conserve forest resources through effective utilization of recovered paper.

At our laboratories and paper mills, we work on developing new, environmentally friendly technologies for utilizing recovered paper.

In addition, we seek to further expand our use of resources, by introducing processing facilities for recovered paper

—including confidential documents—that had been difficult to utilize.

SDGs

Recovered paper

utilization rate exceeding 98%

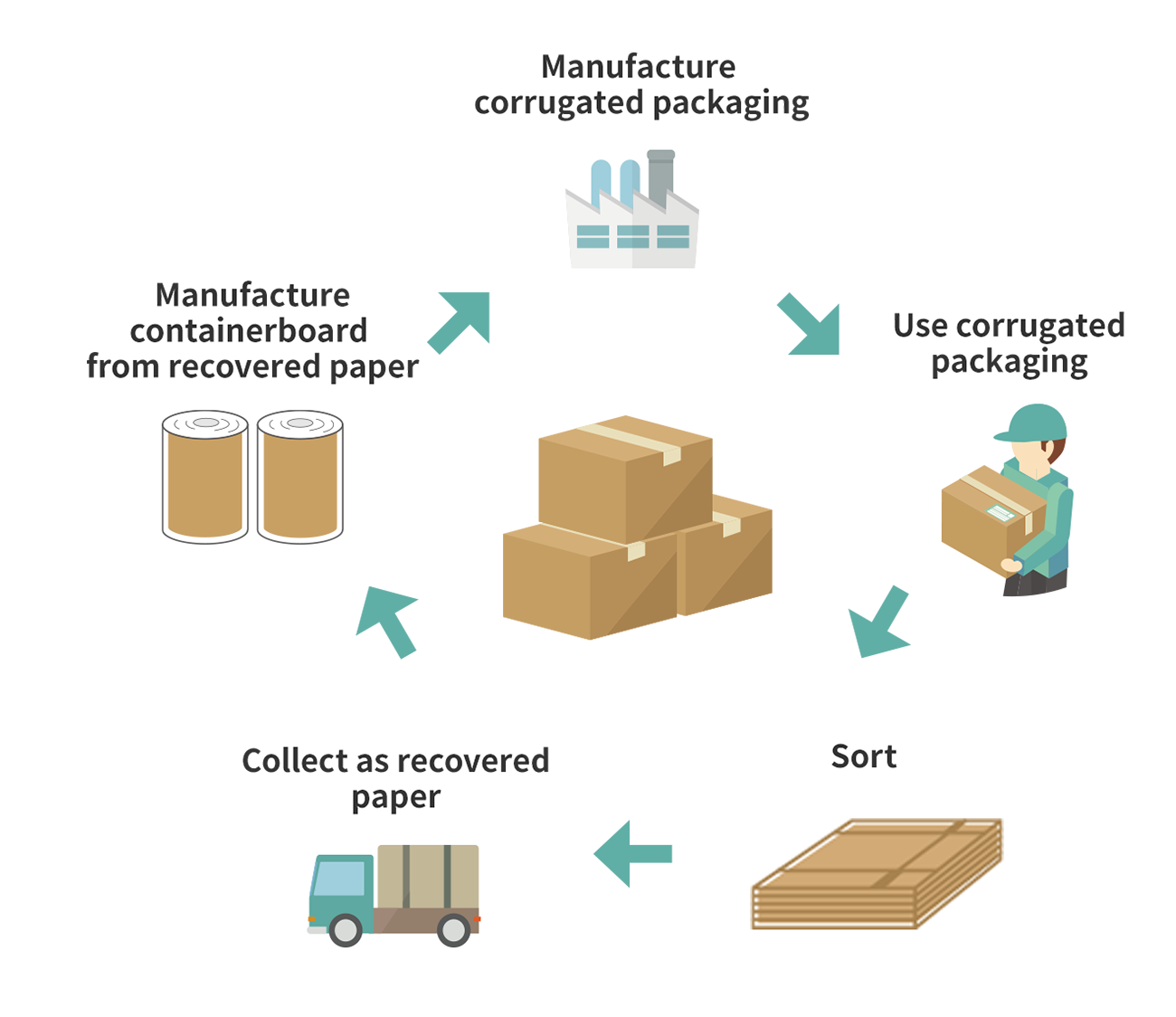

Recycling of corrugated packaging is made up of three sectors: recovered paper, paper, and corrugated packaging. The current corrugated packaging collection system was established as a result of the efforts by the overall industry working as a trinity over many years.

The main product is paperboard, with 98% of the raw materials being recovered paper (recovered paper utilization rate) while the remaining 2% is wood pulp from forest resources.

Together with protecting and developing the trinity of the corrugated packaging recycling system, we are taking solid steps toward a recycling-oriented society while also effectively using limited resources and undertaking new developments.

In addition, the woodchip biomass power plants—which provide electricity for our paper mills—use woodchip from construction waste materials generated in the surrounding regions, contributing toward recycling even in the aspect of energy source.

UseFacing social issues using packaging

Centered on packaging, Rengo develops products that solve various social issues and

are friendly to both people and the environment.

SDGs

Packaging that is friendly to people and the environment

As the workforce shrinks due to lower birthrates and an aging population, the question of how to efficiently perform work with fewer people is becoming a major issue for distribution sites. By refining packaging functionality—such as designs that ease the opening and flattening of corrugated packaging after products are delivered to stores and consumers—we help in solving various social issues.

Rengo Smart Display Packaging

(RSDP)

Reducing work time with easy to open packaging

RSDP is an innovative packaging not only transports and protects products, but also adds the functions of display and sales promotion to improve workability—such as opening and displaying—and enhance sales promotion performance.

- Labor shortage due to

shrinking workforce - Significant reduction in

packaging materials

FSC-certified products

Contributing to appropriately

managed raw material procurement

Ahead of the rest of the industry, we acquired FSC certification in 2016 for all of our paper mills, corrugated plants, and folding carton plants, and established a nationwide supply system for certified products.

* FSC certification is an international system for authenticating and certifying the appropriate processing and distribution of lumber and recyclable resources harvested from appropriately managed forests.

- Appropriately managed raw material procurement

Gemini packaging system

Bringing efficiency to

e-commerce logistics

Gemini is an automated packaging system for the e-commerce market. Besides allowing less materials to be used compared to existing regular boxes, it also brings significant efficiency to packaging processes that relied on human labor.

- Streamlining the packaging process

- Reduction of environmental impact by also improving transportation efficiency

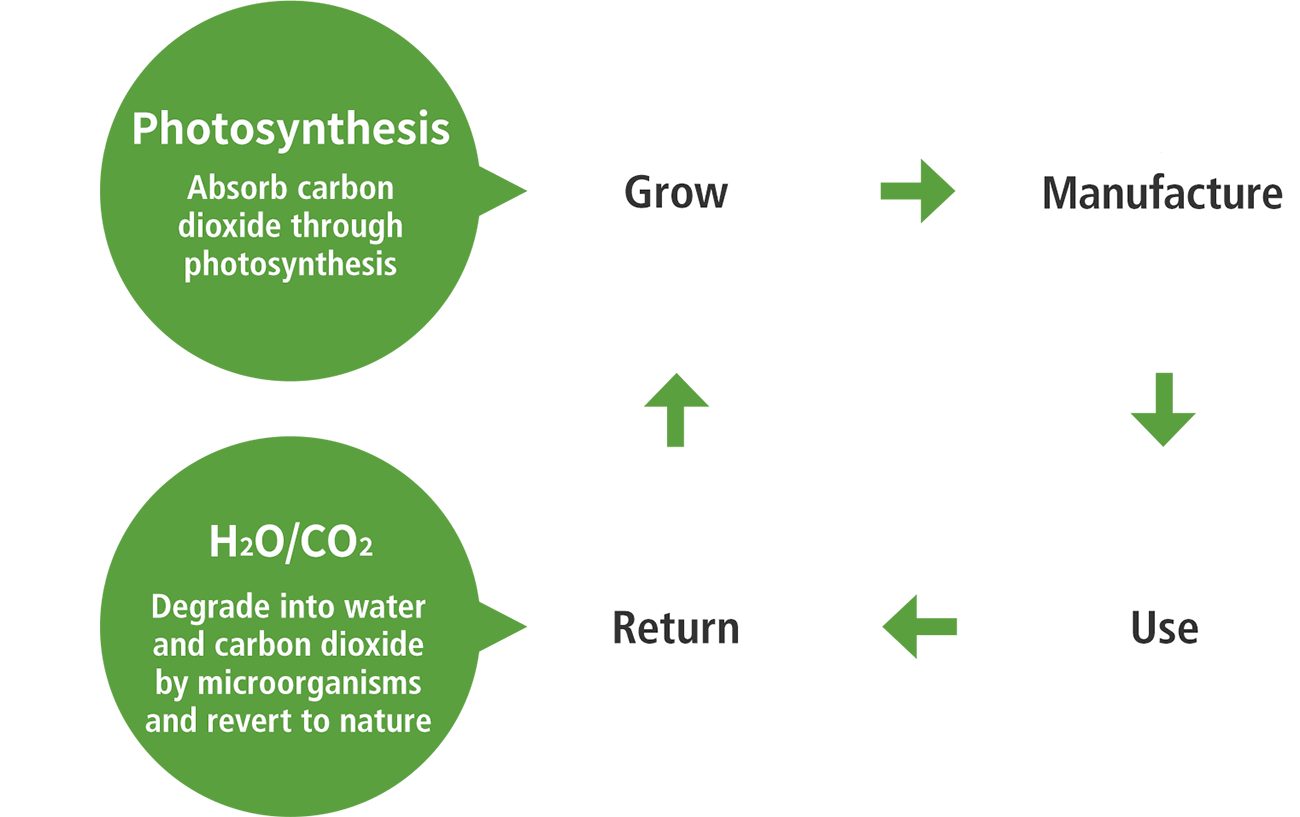

ReturnDeveloping materials that degrade in nature

Ocean plastic waste is becoming a major issue globally.

To protect our clean and oceans, we are leveraging the technologies we have developed

over the long history to research and develop biodegradable materials.

SDGs

Products with the ability to solve issues

Biodegradable materials are materials that are able to degrade into water and carbon dioxide by microorganisms found in seawater and soil . As they revert to nature, they can replace plastics to help reduce the environmental impact caused by plastic waste.

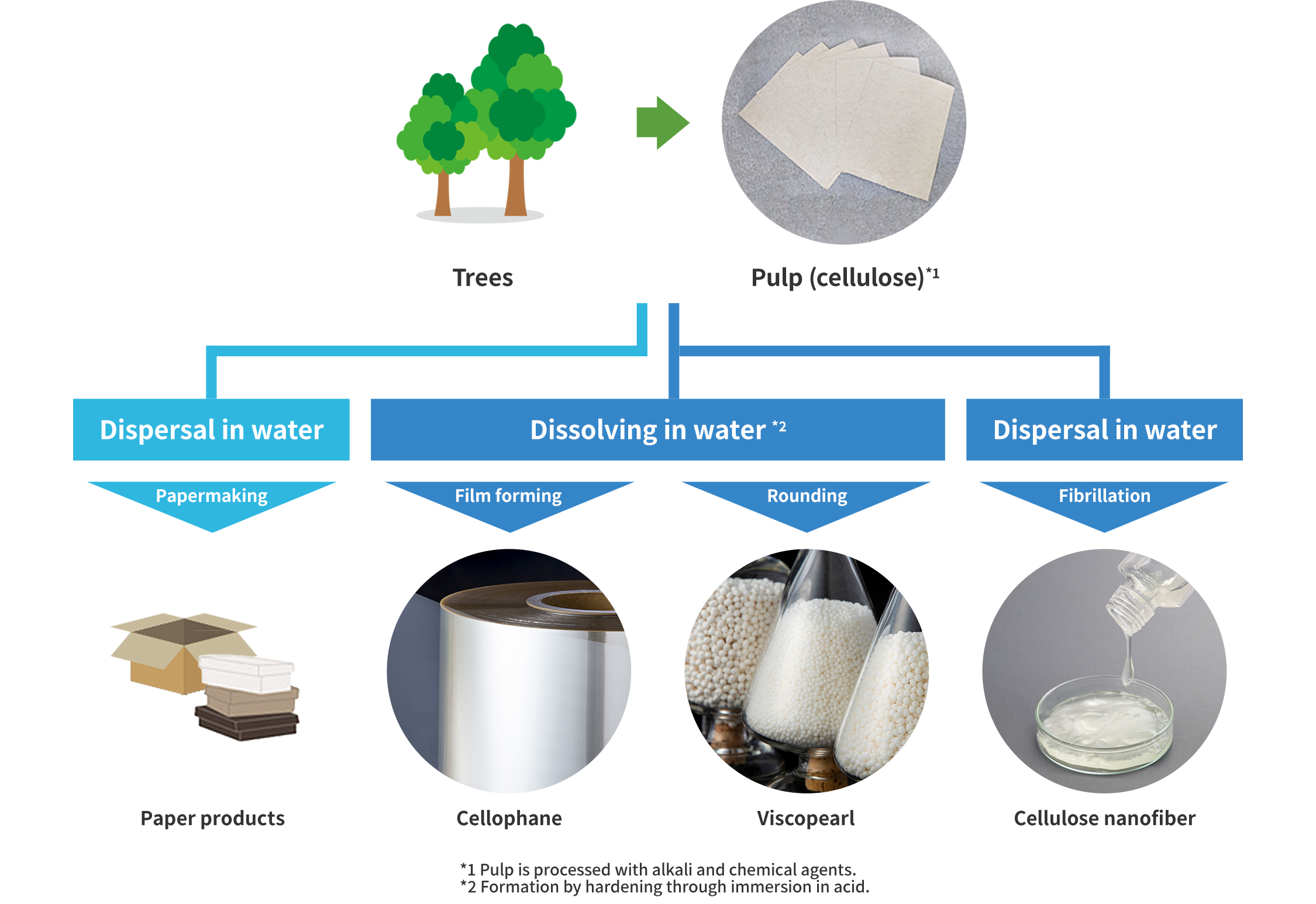

Rengo has a long history of developing biodegradable materials. Beginning in 1934 with the production of cellophane, which uses wood pulp (cellulose) as its raw material, we have been undertaking the development of cellulose-related products even before ocean plastics became a global issue. We will continue to develop new biodegradable materials unique to Rengo.

Biodegradable materials

Cellophane and Viscopearl (Spherical Cellulose Beads), which uses wood pulp as the raw material,

are biodegradable materials representative of Rengo.

Demonstrating excellent biodegradability in seawater, which has fewer microorganisms than in soil,

they have acquired two international certifications: OK biodegradable MARINE for

marine biodegradability and OK biodegradable SOIL for soil biodegradability.