Functional Materials Products

-

Cellulose products

Spherical Cellulose Beads (Viscopearl)

Viscopearl

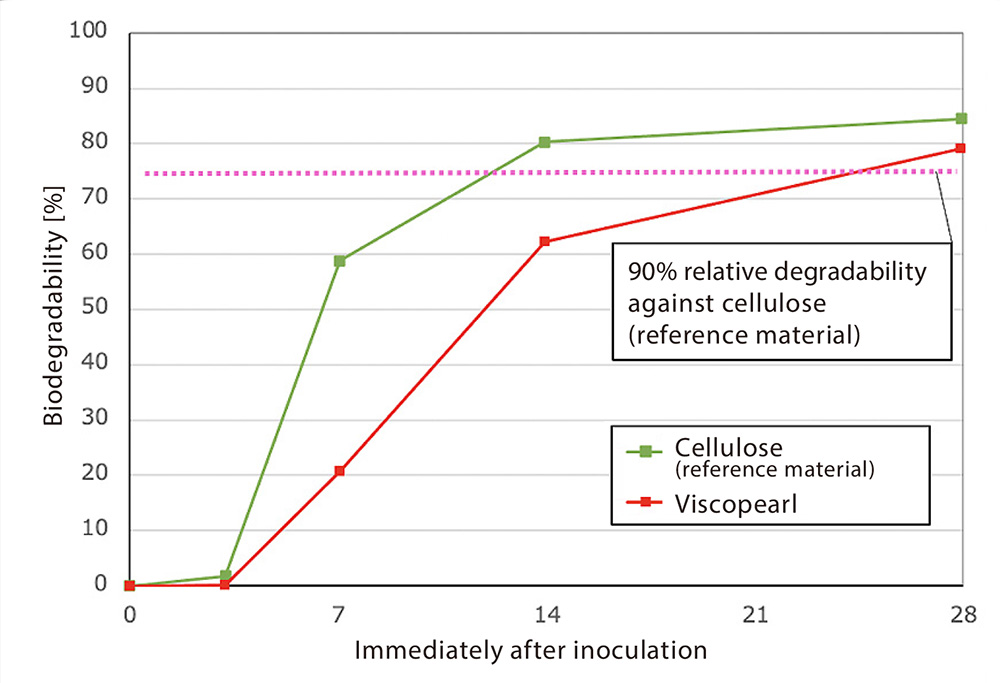

Viscopearl is a spherical cellulose bead made from wood pulp. This product is friendly to forest conservation, using FSC®-certified raw materials, offering a wide range of particle sizes from a few micrometers to 4mm. Biodegradable not only in soil but also in seawater, it is the most appropriate alternative for plastic microbeads.Marine biodegradability

It is an environmentally friendly material that is degraded into water and carbon dioxide gas by microorganisms found not only in soil but also in seawater, and has obtained OK biodegradable MARINE certification, an international certification for marine biodegradability. In recent years, marine pollution caused by microplastics has become a global issue. Viscopearl can contribute toward reducing ocean microplastic waste by replacing plastic beads that may be discharged into the sea.-

-

Certified grades: 3μm to 300μm products

Certified grades: 3μm to 300μm products

Features

- •

- High heat resistance makes it hard to deform even at high temperatures.

- •

- Resistant to chemicals and stable even against organic solvents.

- •

- Smooth texture as it is a spherical bead and does not easily lower fluidity when used as an additive.

- •

- High affinity for both water and oil, and disperses especially well in water.

Product lineup

Item number Particle Size Structure Bulk specific

gravity (g/ml)Features

AH-4050L

4mm

Porous

0.1

Lightweight, water absorbency,

oil absorbencyAH-2050L

2mm

Porous

0.1

Lightweight, water absorbency,

oil absorbencyPD-5002

500μm

Porous

0.3

Lightweight, scrub effect, water absorbency, oil absorbency

PD-3002

300μm

Porous

0.3

Lightweight, scrub effect, water absorbency, oil absorbency

ND-2010

200μm

Non-porous

1.0

Scrub effect, water absorbency, oil absorbency

D-30

20-40μm

Non-porous

0.8

High-slipperiness, water absorbency, oil absorbency

D-10

10-13μm

Non-porous

0.7

high-slipperiness,

water absorbency,

oil absorbency, Soft focus effectD-5

7-10μm

Non-porous

0.6

high-slipperiness,

water absorbency,

oil absorbency, Soft focus effectD-3

< 6.5μm

Non-porous

0.5

high-slipperiness,

water absorbency,

oil absorbency, Soft focus effect* The values for particle size and bulk specific gravity are reference values and not specifications.-

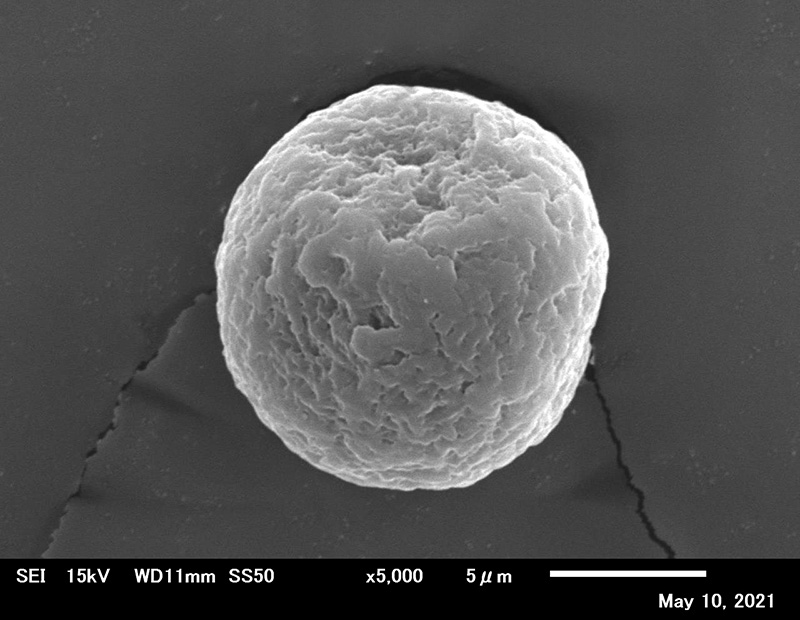

10μm (Non-porous)

10μm (Non-porous)

-

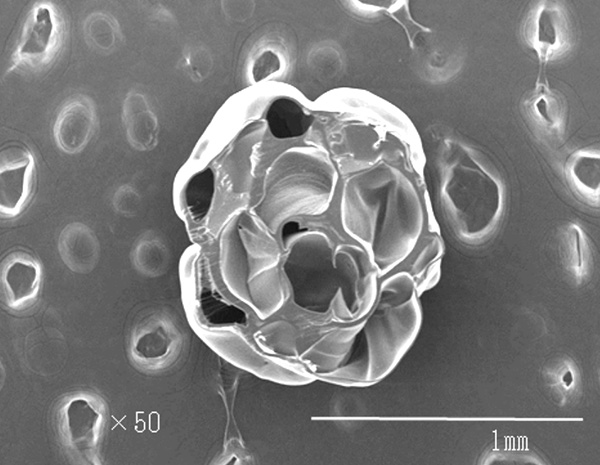

500μm (Porous)

500μm (Porous)

-

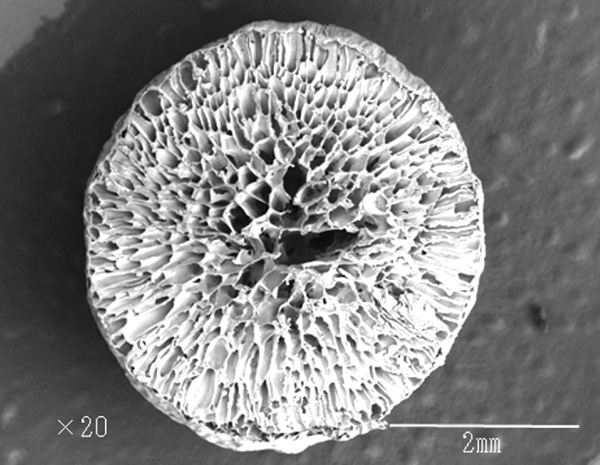

4mm (Porous)

4mm (Porous)

Applications

Viscopearl can be used as a carrier for aromatic agents or functional chemicals, raw material for cosmetics*, or abrasive. It can also be used as an additive for resin and rubber by utilizing features of cellulose such as water absorbency. In addition, the small particle size products (D-10, D-5, and D-3) have a light diffusion effect, enabling them to be used as ink matting agents and light diffusing agents.* Viscopearl as a raw material for cosmetics is sold by DAITO KASEI KOGYO CO., LTD. under the product name CELLULOBEADS.Embedding technology

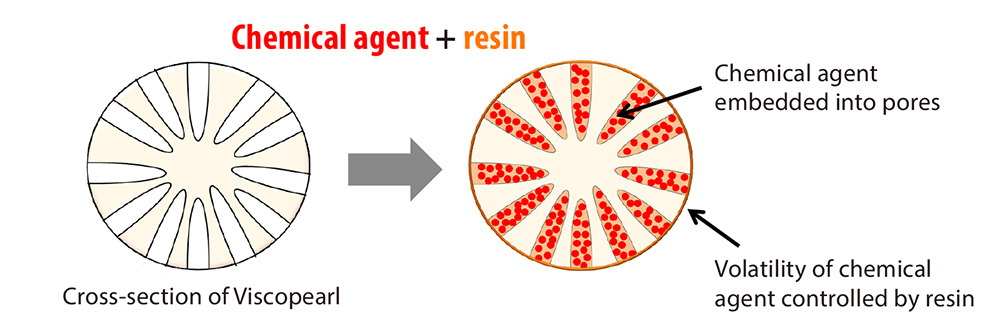

Viscopearl has particle sizes of 2mm and 4mm and has a porous structure and the pores can carry functional chemicals such as aromatic agents and antibacterial agents. Chemical agents can be stabilized and their volatilities are controlled by embedding processing that mixes chemicals with a special resin that is then carried by Viscopearl.Concept of embedding technology

Fragrance testers

These are fragrance testers loaded with aromatic agents by embedding technology. Cellulose has high chemical stability and does not change aromatic agents' composition quality, making it suitable for long-term controlled release. Viscopearl can also be colored according to the aroma.-

Bottle-type

-

Product packaging-type

-

Push-type

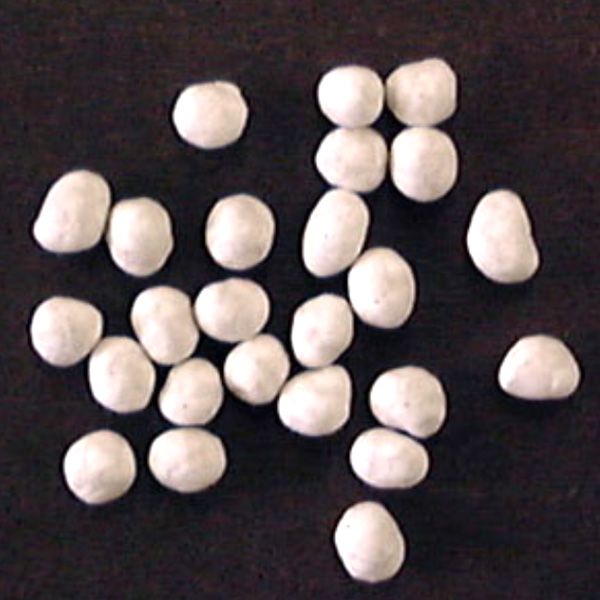

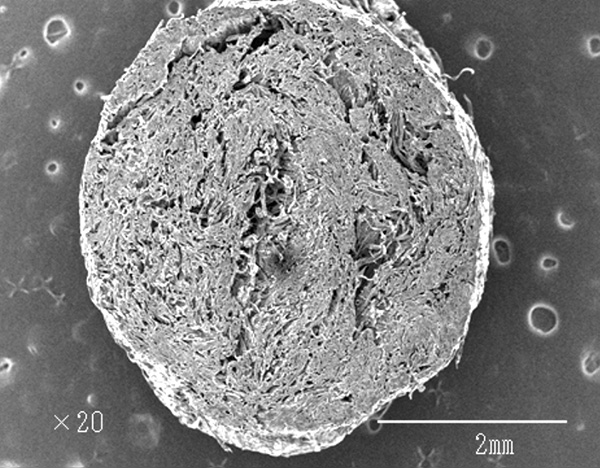

Viscopearl P

These particles are mechanically granulated using wood pulp fiber as the main raw material. The particles have continuous porous structure with a pore diameter of approximately 10μm. They can be used not only as a carrier for liquids, but also conjugated with fine powders such as activated carbon to create compound beads.-

Appearance

Appearance

-

Electron microscope photo

Electron microscope photo

Conjugation technology

- It is possible to create compound beads by mixing with powders during the manufacturing process of Viscopearl P. By conjugating small particles with Viscopearl P, it makes handling easier without impairing functions as a powder.

-

Viscopearl P conjugated with activated carbon

Viscopearl P conjugated with activated carbon

〈 For inquiries regarding all Functional Materials Products 〉

e-mail: gnavi@rengo.co.jp

〈 For inquiries regarding raw material for cosmetics 〉

DAITO KASEI KOGYO CO., LTD. https://www.daitokasei.com/en/company/profile.html

-