Creativity and Research & Development

The evolution of packaging is supported

by the latest research and development capabilities.

Research & Development

Changing the future of packaging with unprecedented functions,

materials, and manufacturing technologies

-

As the first company in Japan to become involved in the corrugated business, and lead the industry as a pioneer, Rengo has continued to develop numerous innovative functions, materials, and manufacturing technologies which open up the possibilities of packaging. We support ever-evolving packaging with the latest research and development capabilities, including paperboard production technology that achieves lightweight containerboard; functional corrugated packaging such as water resistance, moisture proofing, fire retardancy, and low friction; and development of adhesives that improve production efficiency.

-

-

Low friction corrugated board

Low friction corrugated board

COSREN -

Fire-retardant corrugated board

Fire-retardant corrugated board

RAFEP

-

-

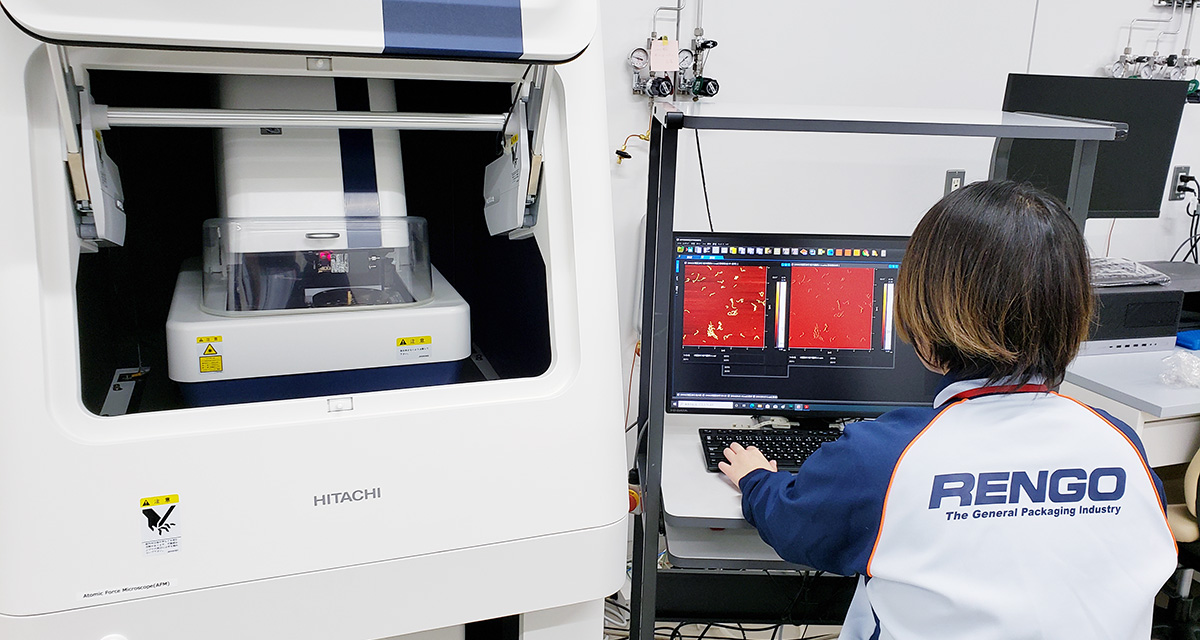

Morphological observation of cellulose nanofibers with an atomic force microscope

Morphological observation of cellulose nanofibers with an atomic force microscope -

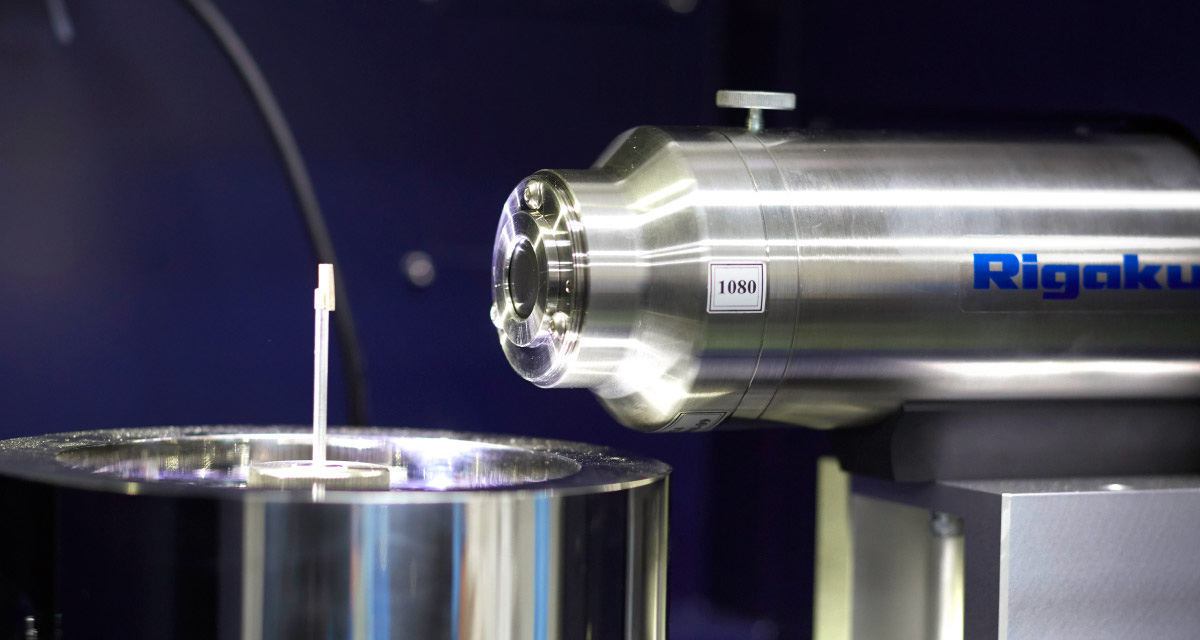

Observation of the internal structure of corrugated board using an X-ray CT scanner

Observation of the internal structure of corrugated board using an X-ray CT scanner

Developing a variety of functional materials

beyond packaging to make life comfortable

-

Rengo developed a series of sustainable package branded as REBIOS, with a sense of mission to contribute to solving environmental issues and marine plastic problems. REBIOS utilizes cellophane and paper and has biodegradability and high biomass content. Other than packages, Rengo has developed zeolite high-density crystallized pulp called Cellgaia, which is also widely used such as in antibacterial kitchen cloths. Moreover, Rengo is conducting research and development for the practical applications of cellulose nanofibers, which are attracting attention from various industries.

-

-

Plastic Alternative Packaging

Plastic Alternative Packaging

REBIOS -

Product containing Cellgaia

Product containing Cellgaia

Antibacterial kitchen cloth -

Cellulose fiber

Cellulose fiber

Cellulose nanofiber

-

Bringing innovation to packaging through research and development

in collaboration with design and manufacturing frontlines

- To meet high-level needs, it is important to not only develop new functions, but also improve quality from various angles, such as planning, manufacturing, and design. At Rengo, we give birth to many innovative packaging solutions by carrying out research and development while sharing and collaborating on issues with various units.

-

-

Beverage labels with low environmental impact

Beverage labels with low environmental impact

Rengo has developed manufacturing technologies incorporating new technologies and materials such as water-based flexo printing technology, inks made from biomass, and the use of film and so on. -

Digital pre-printing

Digital pre-printing

Rengo has achieved highly-decorative customizable printing with content that can be changed per sheet.

-

-

Checking the color tone of printing ink with a digital microscope

Checking the color tone of printing ink with a digital microscope -

Film strength test using a tensile tester

Film strength test using a tensile tester

Pursuing safety and peace of mind is also

the responsibility of a leading company

Rengo—which also offers many packaging products for food and beverages—conducts chemical analysis on material properties, product quality, impact on the environment, and so on. We believe that the pursuit of safety and peace of mind is the responsibility of a leading company, and also work on improving analysis technology.

-

Examination of resin composition using a desktop kneader

Examination of resin composition using a desktop kneader -

Analysis of trace components in products with a gas chromatograph-mass spectrometer

Analysis of trace components in products with a gas chromatograph-mass spectrometer

Major products developed by the Central Laboratory

Recyclable corrugated products

Cellulose beads

High-function fiber

-

Central Laboratory, Osaka

4‐1‐186 Ohiraki, Fukushima-ku,

Osaka, Japan 553-0007

TEL. +81-6-6465-5067 FAX. +81-6-6465-0220

Central Laboratory, Fukui 1-8-10 Jiyugaoka, Awara-shi,

Fukui Prefecture, Japan 919-0604

TEL. +81-776-73-7037 FAX. +81-776-73-7041