History of Rengo

-

Changing times and the history of Rengo

- Teijiro Inoue makes

Japan's first corrugated board -

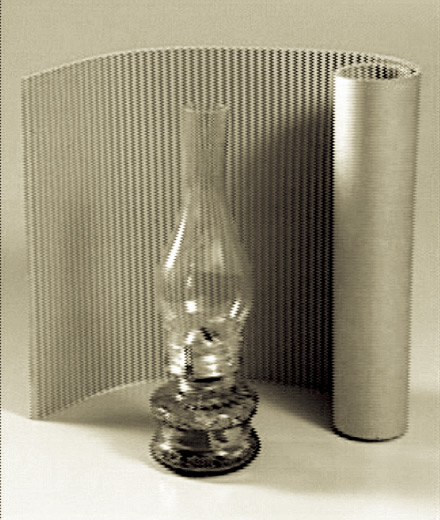

Corrugated board used to wrap around and protect a lamp

- 1909

- World War I

Establishment of various new industrial facilities

- Teijiro Inoue made up his mind to become an independent self-employed businessman (and later made April 12, the day of his decision, the company's Foundation Day)

Established Sanseisha in Shinagawa, Tokyo, setting up Japan's first corrugated board business

Coining of the Japanese term for single faced corrugated board, "danboru" which is still used today

- 1920

- Great Kanto Earthquake

Taisho Democracy

-

Five companies merged to form Rengo Shiki K.K., capitalized at ¥2 million

Acquired Nippon Seishi and renamed it the Chifune Plant

The head office, Tokyo Plant and other facilities were destroyed by fire after the earthquake, and the head office was relocated to Osaka

Began sale of applied products (larval silkworm raising boxes and clothing boxes)

- 1930

- Showa Financial Crisis Expansion of exports February 26 Incident

World War II

-

Completed construction of the Yodogawa Plant, which employed an integrated production system, from containerboard to corrugated board

Met a wider range of demand that included home appliances, canned foods, bottled beer, ceramics, and clothing

Established new plants and subsidiaries in Korea, Taiwan and China

Formed a capital tie-up with Tokyo Electric (current Toshiba)

- From wooden boxes

to corrugate packaging - 1940

- Pacific War

Promulgation of the Constitution of Japan

Outbreak of the Cold War

Production to meet military demand under wartime economic control

-

Six domestic plants were destroyed by fire during air raids, and overseas assets were lost

Resumed production to meet consumer needs and developed new demand for corrugated boxes for frozen whale meat and canned foods

Obtained a listing at stock exchange and increased capital to ¥10 million

- Sudden increase in

corrugated board production together

with rapid economic growth - 1950

-

San Francisco

Home electric

Peace Treaty

"We are no longer in

the postwar period."

appliance boom -

Corrugated boxes were increasingly used for mandarin oranges, apples, and frozen fish.

Modernized production equipment to meet growing demand

Opened Research Laboratory (later, Central Laboratory)

“Ruten” boom as Teijiro Inoue's autobiography was adapted for TV and film

-

Advertising poster for corrugated packaging

- 1960

- Trade liberalization

Tokyo Olympic

Games

Japan attains world's

second largest GNP - Built Tonegawa Mill, as well as new corrugated plants

Introduced technology from the United States as the functions of corrugated boxes diversified

Developed GRAVIAN and other pre-printed corrugated boxes

- 1970

-

Japan World

Second Oil Crisis

Exposition

Plan for the

remodeling of the

Japanese archipelago

First Oil Crisis -

Rengo Shiki K.K. renamed Rengo Co., Ltd.

Developed CORFLEX five-color pre-printed corrugated box

Developed continuous running technology for corrugator operation

Developed and commercialized “Fingerless Single Facer”

Exported Rengo's technologies for producing paperboard and corrugated board

- 1980

- Recession caused

by the strong yen

Prolonged

economic boom

Cold War ends with

collapse of

the Berlin Wall

Land and stock price boom - Built a series of new corrugated plants

Expanded business to cover nonwovens and other peripheral areas

Opened new office in Singapore for overseas expansion

- 1990

- End of "bubble

economy"

Multiple recessions

Great Hanshin-

Awaji Earthquake

Creation of the

euro currency

“Lost Decade” and

zero interest policy -

Ventured into overseas business with Malaysia as a start

Opened Packaging Technical Center

Acquired Fukui Chemical Industry, an affiliated company

Incorporated Howa Sangyo into Rengo Group to enter the flexible packaging business

Acquired Settsu to reinforce the integrated paper and corrugated board production system

-

Fire-retardant corrugated board RAFEP that does not catch fire easily even though it is made from paper

- 2000

-

"No-holds-barred

structural reforms"

Terrorist attacks on

the United States

Massive tsunami off

SumatraBeijing 2008 Olympics

Steep rise in the

prices of crude oil

and other resources

Global financial crisis -

Made Marusan Paper Mfg. Co., Ltd. a group company

Bolstered energy conservation equipment, including biomass incineration power plant

Merged Kawasaki Plant with Katsushika Plant to become folding carton production location on East Japan

Installed a photovoltaic power generation system at the Kyoto Plant

Shin-Kyoto Division commenced integrated production of corrugated board/boxes and folding cartons after merger of the Kyoto and Katsura plants

Rengo's 100th anniversary (April 12, 2009)

Made Nihon Matai Co., Ltd. a group company, and entered into the heavy duty packaging business

- 110th anniversary since

corrugated board made

its appearance in Japan - 2010

-

World Expo 2010

Shanghai

Great East JapanEarthquake

Abenomics

-

New paper mill, a joint venture in Vietnam, begins full-scale operation

Completed construction of the Fukushima-Yabuki Plant which uses photovoltaic power generation to supply all the plant's daytime electricity needs

Completed construction of the Shin-Sendai Plant in about a year after its predecessor, the Sendai Plant, suffered extensive damage in the Great East Japan Earthquake

Completed construction of the Shin-Nagoya Plant, which features one of Japan's largest seismically isolated automated warehouses

Completed PM8 for linerboard production at Marusan Paper Mfg.

Made Tri-Wall Holdings Limited a group company

Completed conversion of Kanazu Mill's PM2 to produce both corrugating medium and linerboard

Made Toppan Containers Co., Ltd. a group company (current RG Containers Co., Ltd.)

- 2020

- Spread of COVID-19

Tokyo 2020 Olympics Games

- Made Taiko Paper Mfg., Ltd. a group company , and entered into the kraft pulp and kraft paper business

Opened Yodogawa Logistics Center as a logistics center for containerboard

Installed biomass boiler facility for power generation at Tonegawa Division

Relocated Matsuyama Plant and established Ehime-Toon Plant

Expo 2025 Osaka, Kansai, Japan

- Teijiro Inoue makes