News Releases / 2017

-

November 14, 2017

Rengo Completes Conversion of Kanazu Mill's No. 2 Paper Machine to Produce Both Corrugating Medium and Linerboard

Rengo Co., Ltd. (Head Office: Kita-ku, Osaka; Chairman, President & CEO: Kiyoshi Otsubo) announces the completion of conversion of its containerboard machine at Kanazu Mill (Awara-shi, Fukui Prefecture) from one dedicated to producing corrugating medium into one also capable of producing linerboard.

In addition to conversion of the machine, the stock preparation process, which greatly affects the quality of containerboard, has also been revamped to further improve product quality. At the same time, the paper machine has been made to meet the rising demands for lightweight containerboard due to environmental considerations, and reborn as a cutting-edge equipment dedicated to saving both energy and resources.

Currently, Rengo Group produces containerboard at six mills in Japan. This conversion was conducted as part of the work currently underway to restructure the production system and consolidate to five mills. Consolidation will increase the operating rates of paperboard mills, and at the same time improve the supply and demand balance of linerboard and corrugating medium, thereby further strengthening the foundation of the paper business.

Rengo Group has many plants in Fukui Prefecture, including Kanazu Mill. With this conversion, Rengo Group hopes to continue supporting the further economic growth of Fukui Prefecture through packaging, and at the same time contribute to the local community such as by boosting employment.

-

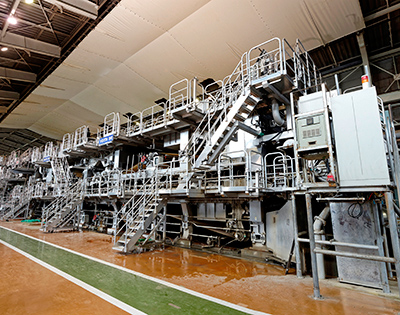

Wire part of Kanazu Mill's No. 2 Paper Machine

-

Front view of paper machine from reel part

Overview of Converted Paper Machine

Mill Rengo Co., Ltd. Kanazu Mill

1-8-10 Jiyugaoka, Awara-shi, Fukui PrefectureEquipment No. 2 Paper Machine

(conversion to produce both corrugating medium and linerboard)Products Containerboard (linerboard and corrugating medium) Type Multi fourdrinier three layers

Paper width 4,500 mm Basis weight Linerboard: 100–210 g/m2; corrugating medium: 90–200 g/m2 Maximum production speed 1,000 m/min Average daily production volume Linerboard: 930 tons/day

(Corrugating medium: 810 tons/day)

-